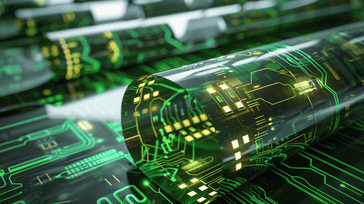

Welcome to the world of printed electronics, where technology meets innovation, and flexible devices are revolutionizing the way we interact with digital gadgets. Printed electronics has emerged as a cutting-edge technology, enabling the production of low-cost, lightweight, and flexible devices that are shaping the future of consumer electronics and smart technology.

With printed electronics, the possibilities are endless. From flexible displays to wearable technology, this innovative approach to electronics is transforming the way we think about electronic devices. By printing electronic components and circuits on flexible substrates, printed electronics opens up a world of possibilities for lighter, more adaptable gadgets that can seamlessly integrate into our daily lives.

Not only does printed electronics offer the potential for more flexible and versatile devices, but it also holds the promise of cost reductions. By utilizing efficient printing processes and materials, manufacturers can streamline production and create affordable solutions for a wide range of applications.

As we delve into the inner workings of printed electronics, we'll explore the materials and techniques used, as well as the diverse applications this technology enables. From wearable sensors to energy storage devices, printed electronics is already making waves across various industries and providing new opportunities for innovation.

In this article, we will take a closer look at the advantages of printed electronics, how it works, current developments, and future trends. By the end, you'll have a deeper understanding of the exciting potential of printed electronics in driving innovation and revolutionizing the world of technology and electronics.

In today's fast-paced world, technology is constantly evolving, and electronic devices are becoming an indispensable part of our lives. Printed electronics has emerged as an innovative solution that revolutionizes the electronics industry, offering numerous advantages over traditional manufacturing methods. From lighter and more flexible devices to cost reductions and new possibilities for smart technology and consumer electronics, printed electronics is shaping the future of technology.

One of the key advantages of printed electronics is its ability to enable the production of lighter and more flexible devices. Traditional electronics rely on rigid circuit boards, limiting the design possibilities and adding weight to the final product. With printed electronics, circuits and components can be directly printed on flexible substrates, allowing for thinner and lighter devices that can be curved or folded.

In addition to flexibility, printed electronics also holds the potential for significant cost reductions in the manufacturing process. Printing electronic components is a simpler and more streamlined method compared to traditional manufacturing techniques, which involve complex fabrication processes. By eliminating the need for costly materials and equipment, printed electronics can lower production costs, making electronic devices more affordable for consumers.

Printed electronics is revolutionizing the field of innovation, opening up new possibilities for smart technology and consumer electronics. The flexibility and cost-effectiveness of printed electronics allow for the development of innovative products such as wearable technology, smart sensors, and flexible displays. These advancements are driving the creation of devices with enhanced functionalities and improved user experiences, pushing the boundaries of what is possible in technology.

"Printed electronics is the future of technology, enabling the creation of lighter, flexible, and more affordable devices, and paving the way for groundbreaking innovations in smart technology and consumer electronics." - [Expert Name], [Company/Organization]

In conclusion, printed electronics offers numerous advantages that have the potential to reshape the landscape of technology and consumer electronics. From lighter and more flexible devices to cost reductions in manufacturing and new opportunities for innovation, printed electronics is driving the evolution of electronics and bringing us closer to a world of smart and connected devices.

Printed electronics is a fascinating field that offers cutting-edge technology and innovation in the world of electronics. It enables the printing of electronic components and circuits on flexible substrates, revolutionizing the way we think about traditional electronics.

The process of creating printed electronics involves the use of advanced printing techniques to deposit functional inks containing conductive, semiconductor, and dielectric materials. These inks are meticulously printed onto flexible substrates, such as plastic, paper, or textiles, using various printing methods like inkjet, screen, or gravure printing.

The materials used in printed electronics are carefully selected to ensure optimal performance and reliability. Conductive inks, for example, contain tiny metallic particles that allow the flow of electricity when properly connected, while semiconductor inks enable the creation of electronic devices like transistors and diodes. Dielectric inks, on the other hand, provide insulation between different layers.

By leveraging this novel printing technology, printed electronics offer a wide range of applications in smart devices and cutting-edge technology. From flexible and wearable electronics to sensors and smart packaging, printed electronics have the potential to transform many industries and enhance the functionality of everyday electronic devices.

Printed electronics pave the way for lighter, more cost-effective, and environmentally friendly electronic devices. They offer unique opportunities for innovation in smart technology and enable the creation of new products that were previously unimaginable.

As the field of printed electronics continues to evolve, researchers and manufacturers are constantly exploring new materials, printing techniques, and applications. With ongoing advancements, we can expect even more exciting developments in printed electronics, driving innovation and shaping the future of technology.

Printed electronics have opened up a world of possibilities for various industries, revolutionizing the functionality of electronic devices and enabling innovative solutions. From wearable technology to flexible displays, sensors, and energy storage devices, the applications of printed electronics are vast and diverse.

Printed electronics have greatly impacted the development of wearable technology, making it lighter, more flexible, and comfortable. With printed sensors, flexible circuits, and integrated power sources, wearable devices such as smartwatches, fitness trackers, and medical patches have become more advanced and user-friendly.

Flexible displays are another exciting application of printed electronics. With the use of printed organic light-emitting diodes (OLEDs) and thin-film transistors (TFTs), manufacturers can create screens that can be curved, folded, or rolled. This opens up new possibilities for devices like smartphones, e-readers, and even rollable televisions.

Printed electronics have also revolutionized the field of sensing technology. Printed sensors can be integrated into various devices, allowing them to measure temperature, pressure, humidity, or even detect gases. These sensors have applications in industries such as healthcare, automotive, and agriculture, enabling smart monitoring systems and improving efficiency and safety.

Printed electronics have the potential to transform the energy storage landscape. Printed batteries and supercapacitors can be integrated into electronic devices, enabling longer battery life and faster charging. This development is crucial for the advancement of portable electronics, electric vehicles, and renewable energy systems.

"Printed electronics have brought about significant advancements in wearable technology, flexible displays, sensors, and energy storage devices, improving the way we interact with electronic devices and opening up new possibilities for innovation in various industries."

With ongoing research and development in printed electronics, we can expect even more exciting applications in the future. From healthcare and transportation to consumer electronics and beyond, the potential for printed electronics to drive innovation and enhance everyday electronic devices is truly remarkable.

In the rapidly evolving landscape of technology and electronics, printed electronics continues to make remarkable strides. Ongoing research and emerging trends in this field are paving the way for exciting developments and shaping the future of digital devices and smart technology.

One of the key areas of focus in current printed electronics research is the integration of cutting-edge technologies. By combining printed electronics with other innovative technologies, such as nanotechnology and flexible displays, researchers are pushing the boundaries of what is possible in the world of electronics.

The application of printed electronics in wearables is another area experiencing significant advancements. From smart fitness trackers to augmented reality glasses, printed electronics enable the creation of lightweight and flexible devices that seamlessly integrate with our daily lives.

The environmental impact of electronic waste has also led to a greater emphasis on sustainable solutions. Printed electronics offer the potential to produce eco-friendly electronic devices that minimize the use of precious resources and reduce waste.

Companies and researchers are also exploring the potential of printed electronics in medical applications. From wearable health monitors to advanced drug delivery systems, printed electronics hold the promise of revolutionizing healthcare technology, making diagnostics and treatments more accessible and efficient.

The future of printed electronics looks incredibly promising. As the field continues to advance, we can expect to see further developments in areas such as energy storage, flexible displays, and Internet of Things (IoT) devices.

"Printed electronics have opened up new avenues for innovation in the world of technology and electronics. Its versatility and potential for cost-effective production make it an exciting area to watch for future developments."

As printed electronics technology evolves, it has the potential to disrupt traditional manufacturing processes and transform numerous industries. The benefits of printed electronics, including cost reduction, flexibility, and sustainability, are driving its adoption and paving the way for new and exciting applications.

With continued research and development, we can expect to see even more groundbreaking innovations in the world of printed electronics. From advanced wearable technology to intelligent packaging solutions and beyond, the possibilities are truly endless.

The future looks bright for printed electronics, where technology, innovation, and smart solutions converge to bring about a new era of electronic devices and technologies that enhance our lives and drive progress.

| Advantages of Printed Electronics | Applications of Printed Electronics | Current Developments and Future Trends |

|---|---|---|

| Lightweight and flexible devices | Wearable technology | Integration of cutting-edge technologies |

| Cost reductions | Flexible displays | Advancements in wearables |

| Driving innovation in smart technology | Sensors | Sustainable solutions |

| Revolutionizing consumer electronics | Energy storage devices | Printed electronics in medical applications |

Printed electronics represents a significant advancement in technology and electronics, paving the way for innovative and flexible devices. The ability to print electronic components on various substrates opens up exciting possibilities for the development of low-cost and lightweight gadgets, revolutionizing the world of digital devices and smart technology.

By harnessing printed electronics, we can expect to see advancements in wearable technology, flexible displays, sensors, and energy storage devices. This technology has the potential to transform multiple industries and enhance the functionality of everyday electronic devices, making them more adaptable and efficient.

As research and development in this field continue to progress, the future of printed electronics looks promising. We anticipate further breakthroughs that will shape the way we interact with technology and revolutionize the electronics market. The integration of printed electronics into our daily lives holds immense potential for both consumers and industries, making technology more accessible and enhancing our overall experience with digital devices and smart tech innovations.

Printed electronics refers to the manufacturing of electronic components and circuits using printing techniques on flexible substrates. This enables the production of lightweight and flexible devices, opening up new possibilities for innovation in technology and electronics.

Printed electronics offer several advantages, including the ability to create lightweight and flexible devices, potential cost reductions in production, and the facilitation of new innovations in smart technology and consumer electronics. These advancements contribute to the development of more efficient and functional electronic devices.

Printed electronics involve the process of printing electronic components and circuits on flexible substrates using specialized techniques. This allows for the integration of electronic functionality into various materials, enabling the production of innovative digital devices with enhanced flexibility and efficiency.

Printed electronics have diverse applications across various industries. They are used in wearable technology, flexible displays, sensors, and energy storage devices. These applications have the potential to revolutionize the way we interact with technology and improve the functionality of electronic devices in our daily lives.

The field of printed electronics is continuously evolving, with ongoing research and development driving new advancements. Current developments include the exploration of novel materials, improved printing techniques, and the integration of printed electronics into Internet of Things (IoT) devices. The future trends of printed electronics involve further miniaturization, increased functionality, and enhanced integration into everyday objects and environments.

Copyright © 2024 Frontier Tech. All rights by Frontier Tech.